MetaPiping

The ULTIMATE design and analysis software for NUCLEAR and INDUSTRIAL piping systems

![]() Qualified for Class 1 calculations, engineered for high-temperature environments, and specially adapted to advanced nuclear technologies including SMRs and fusion reactors

Qualified for Class 1 calculations, engineered for high-temperature environments, and specially adapted to advanced nuclear technologies including SMRs and fusion reactors

![]() Powered by Code_Aster solver

Powered by Code_Aster solver

![]() Open to Python developers

Open to Python developers

![]() Detailed finite element analysis of piping elements

Detailed finite element analysis of piping elements

![]() Validated on more than 200 test cases

Validated on more than 200 test cases

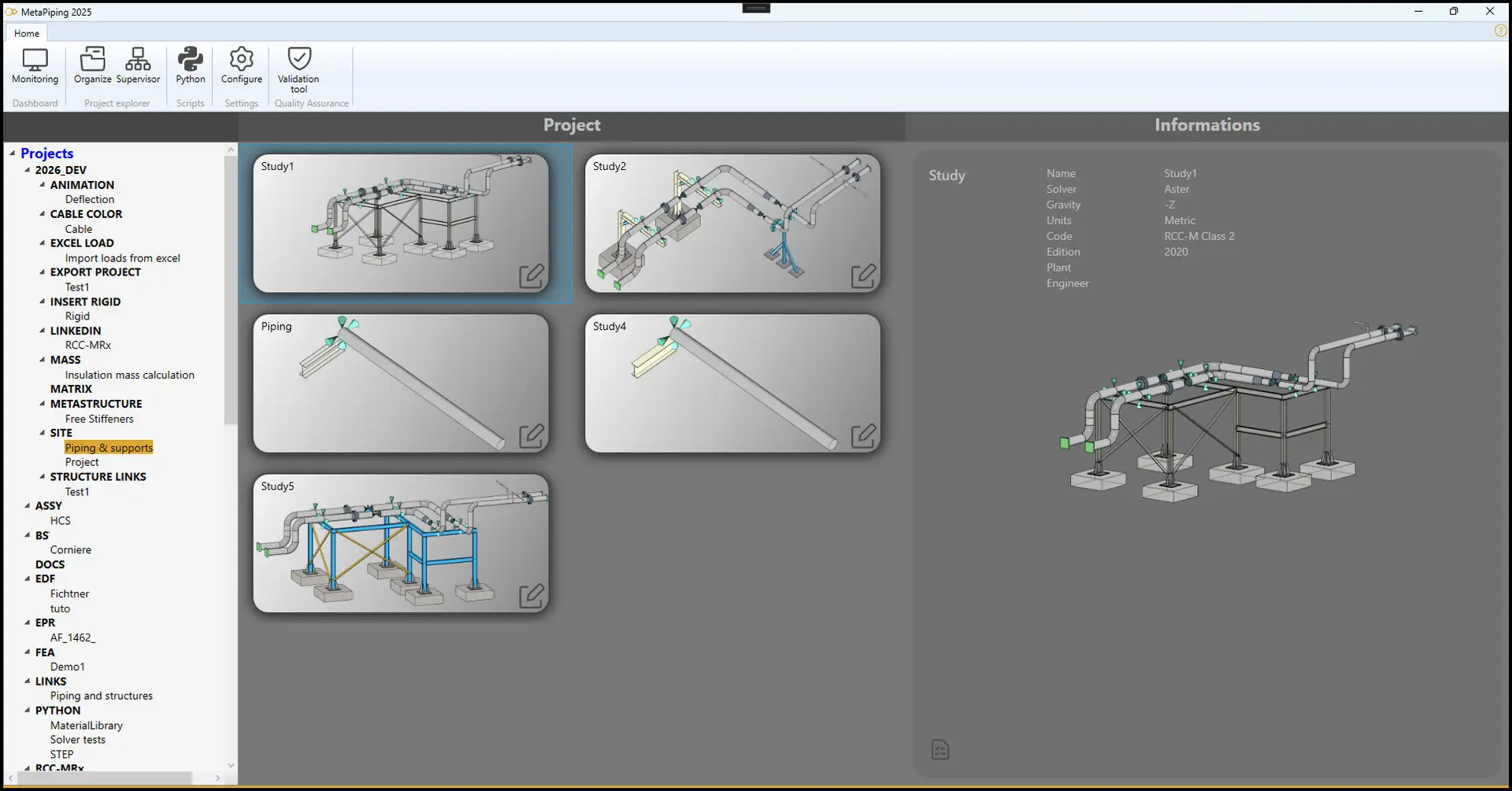

File management

MetaPiping stores the projects in a hierarchical treeview with groups and sub-groups. No more isolated files in the hard disk. This hierarchy can be placed on an internal server and shared for all users.

A project contains a list of studies.

A study contains a 3D model and can be a piping system or a structure. So all supports of a piping can be stored in the same project for example. Smart!

A study can also be duplicated inside a project to make some variations or experimentations. Cool!

Piping engineers can work on piping systems and structural engineers on the structural supports.

A link mechanism allows user to share the 3D model with other studies; a piping system can be drawn based on the support positions or inversely, the structural supports are drawn based on piping positions. Useful!

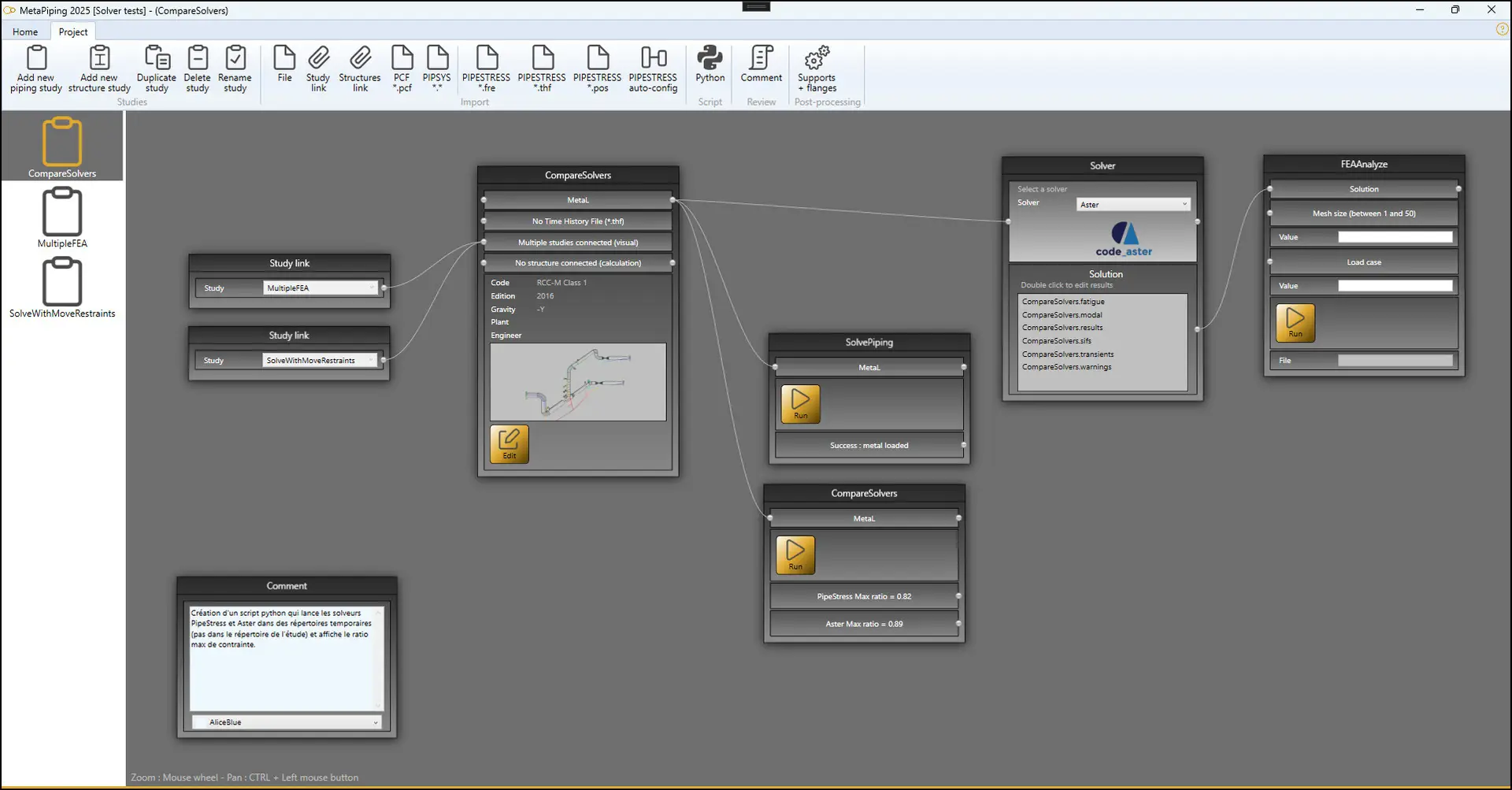

A study is a graph composed of bricks and connections.

Example of bricks:

- 3D model (piping or structure)

- Solver

- Study links

- PCF, Pipsys or PIPESTRESS converters

- Python bricks

- Comments

Databases

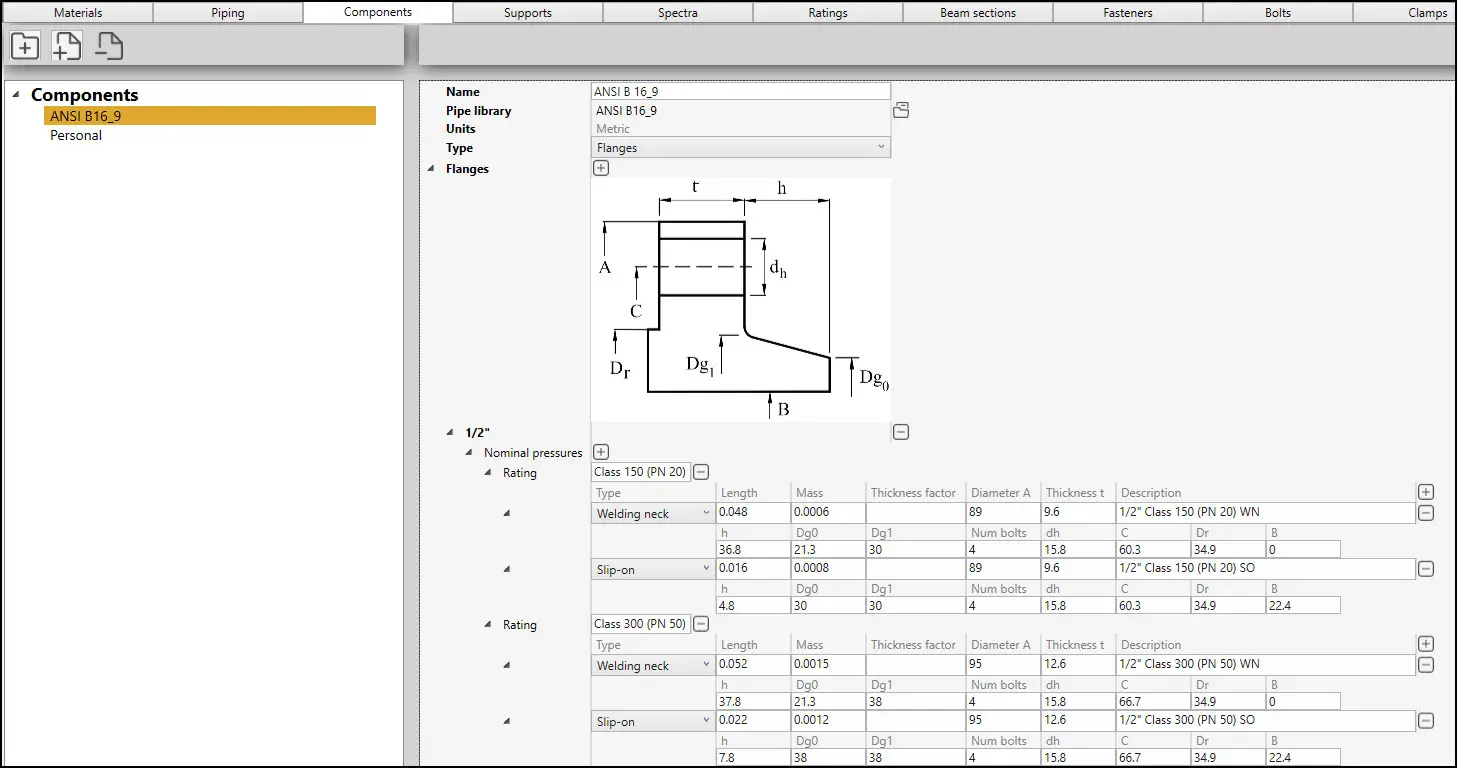

![]() MetaPiping lets you create databases of common data like materials, components, spectra, ratings, beam sections, fasteners, bolts or clamps.

MetaPiping lets you create databases of common data like materials, components, spectra, ratings, beam sections, fasteners, bolts or clamps.

![]() Databases improve the speed of design, eliminate the repetition of encoding from project to project and reduce the risk of error.

Databases improve the speed of design, eliminate the repetition of encoding from project to project and reduce the risk of error.

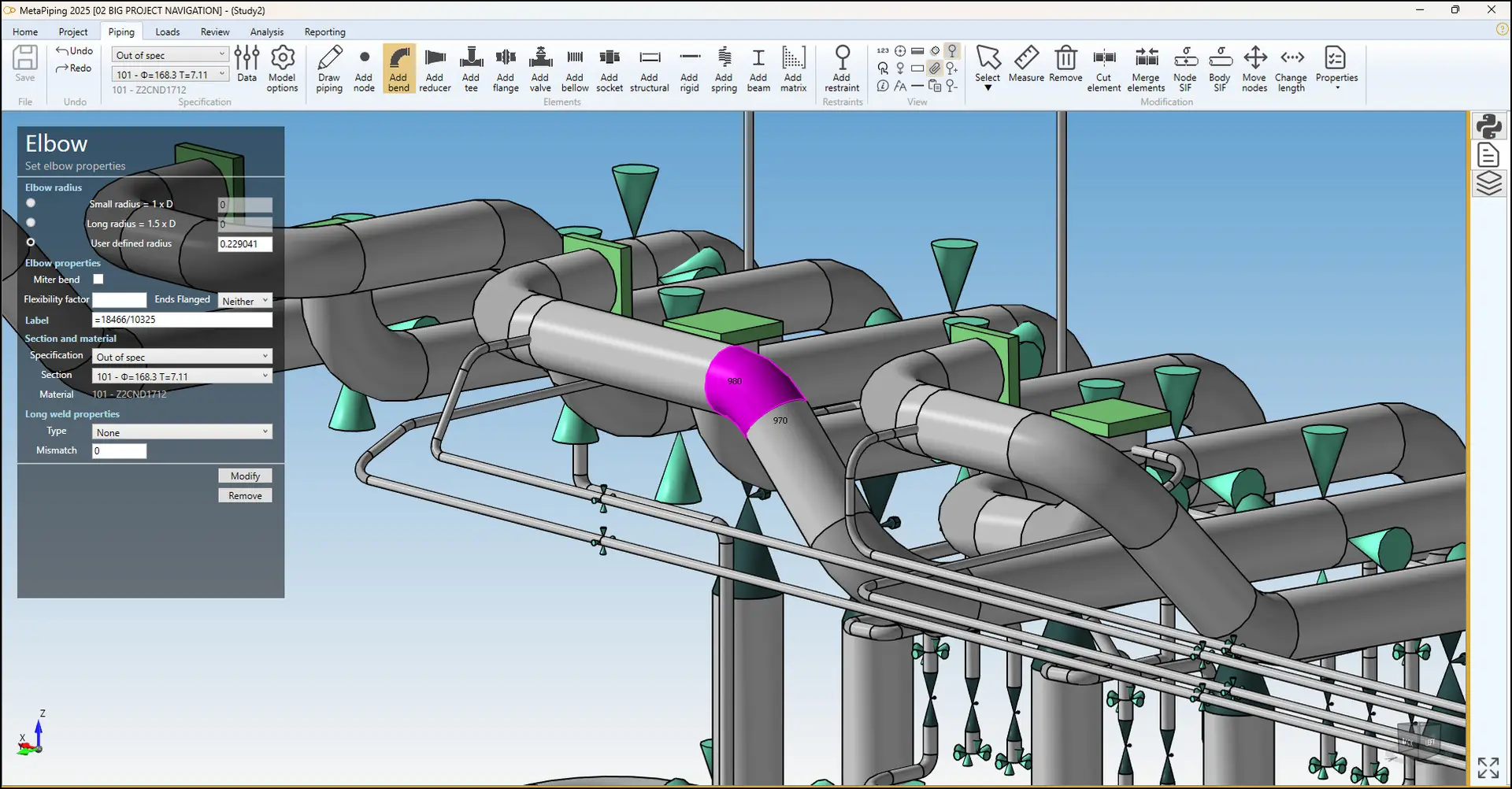

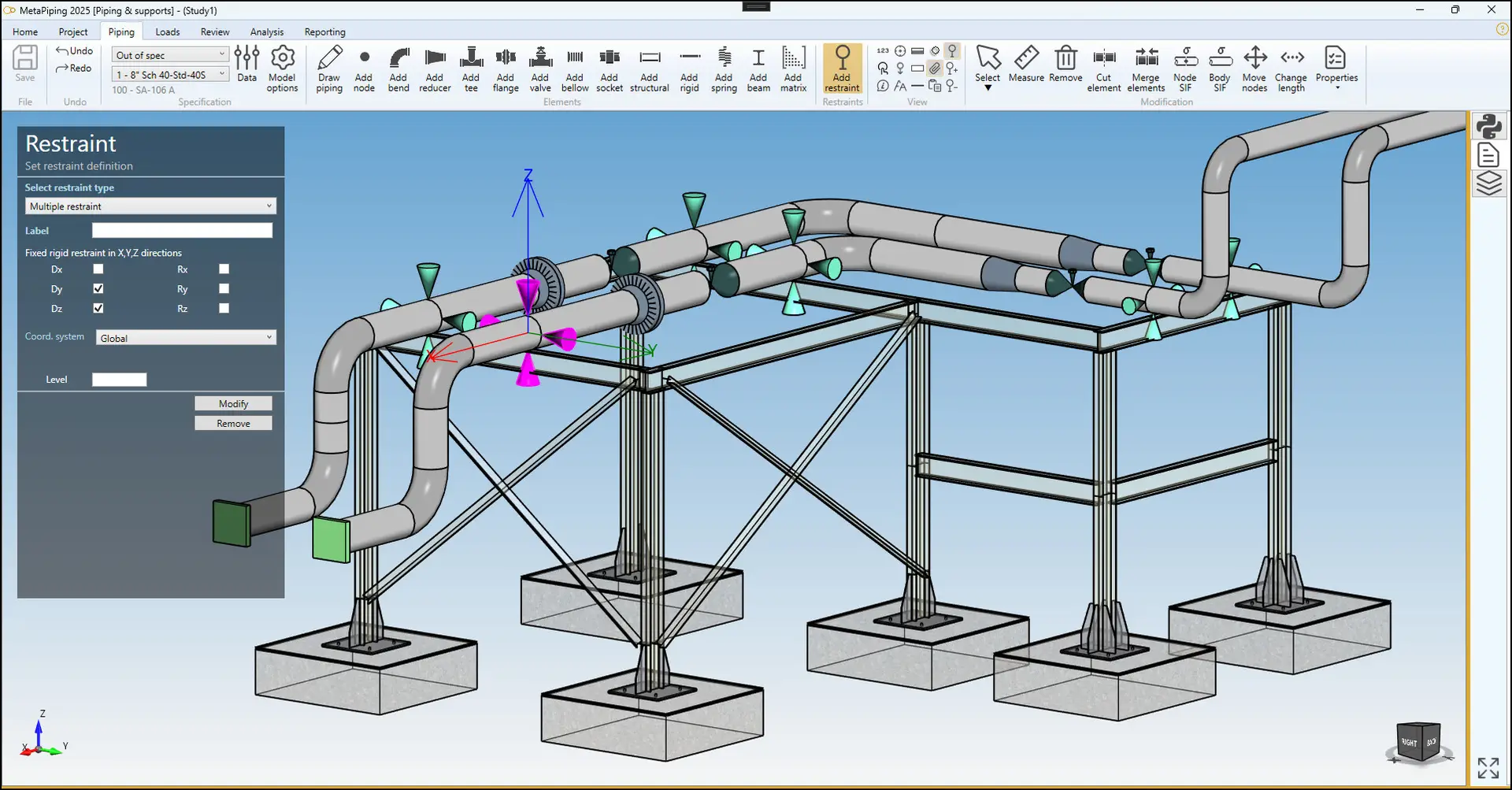

3D engine

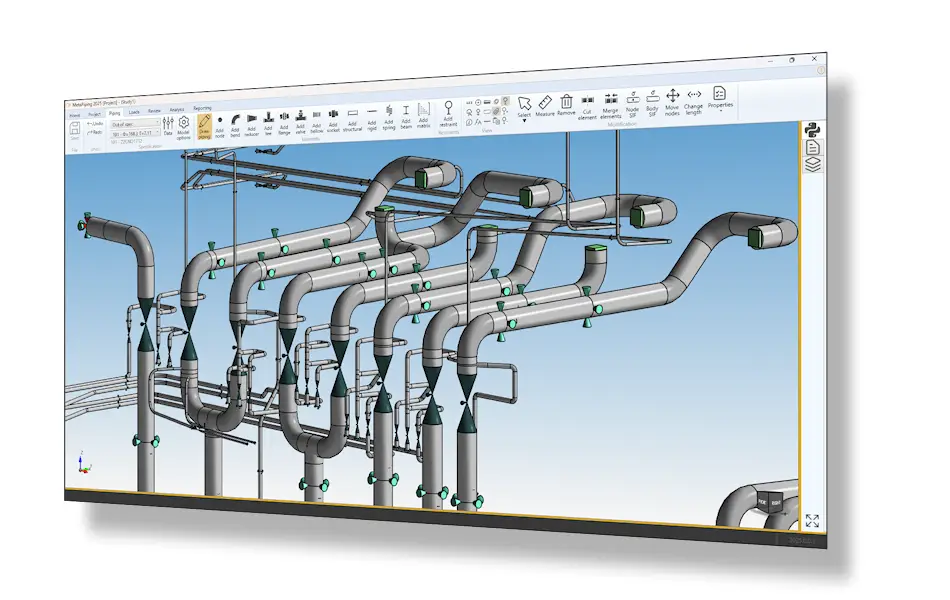

![]() MetaPiping lets you draw as if you were in a CAD software.

MetaPiping lets you draw as if you were in a CAD software.

![]() Draw, select and navigate directly with the mouse.

Draw, select and navigate directly with the mouse.

![]() The 3D engine is optimized for large projects with concepts of layers, solid or wireframe representation and element visibility control.

The 3D engine is optimized for large projects with concepts of layers, solid or wireframe representation and element visibility control.

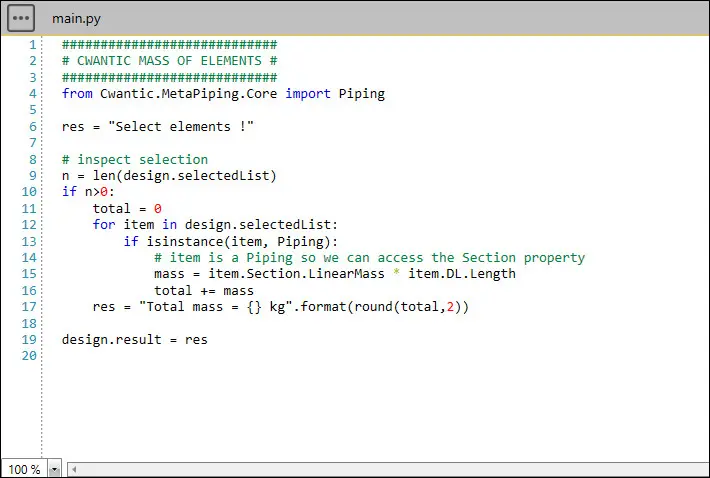

Python

![]() Write your own Python scripts to control the piping model, to create a control Macro or to post-process the analysis results.

Write your own Python scripts to control the piping model, to create a control Macro or to post-process the analysis results.

![]() The scripts can be stored in the design tab, in the load tab, in the review tab or in the analysis tab.

The scripts can be stored in the design tab, in the load tab, in the review tab or in the analysis tab.

![]() You have total control to manipulate all the « classes » of MetaPiping.

You have total control to manipulate all the « classes » of MetaPiping.

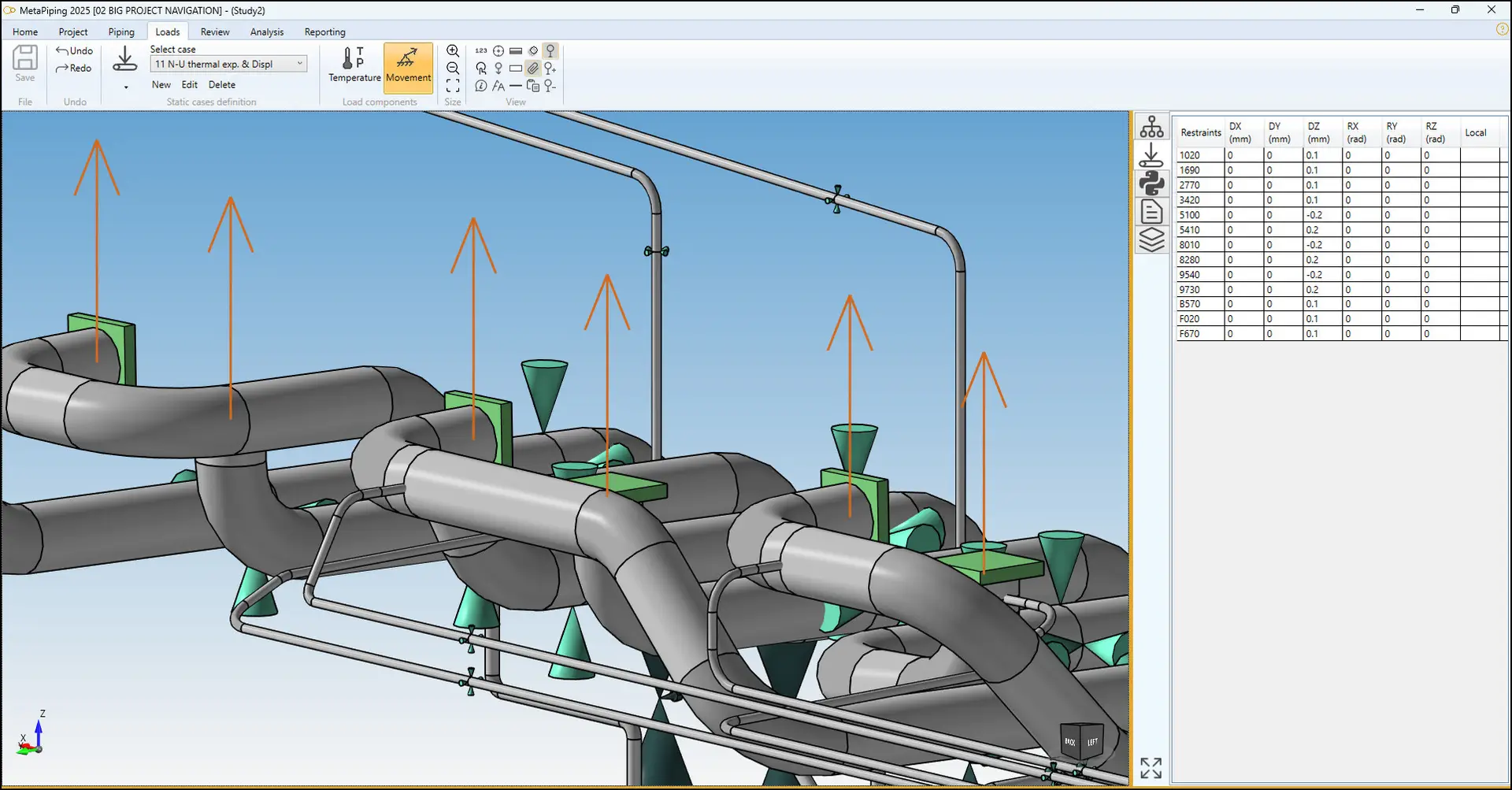

Loads

- Static loads: operating and test weight, thermal expansion, snow and wind, settlement, cold springing, variable pseudo-static acceleration, applied support movements, variable fluid density, distributed forces, horizontal and non-horizontal stratification effects.

- Dynamic loads: uniform and independent support motion using floor response spectra, time-history of forces and moments.

- Combinations of loads.

- Class 1 loads: fluid transients and load sets.

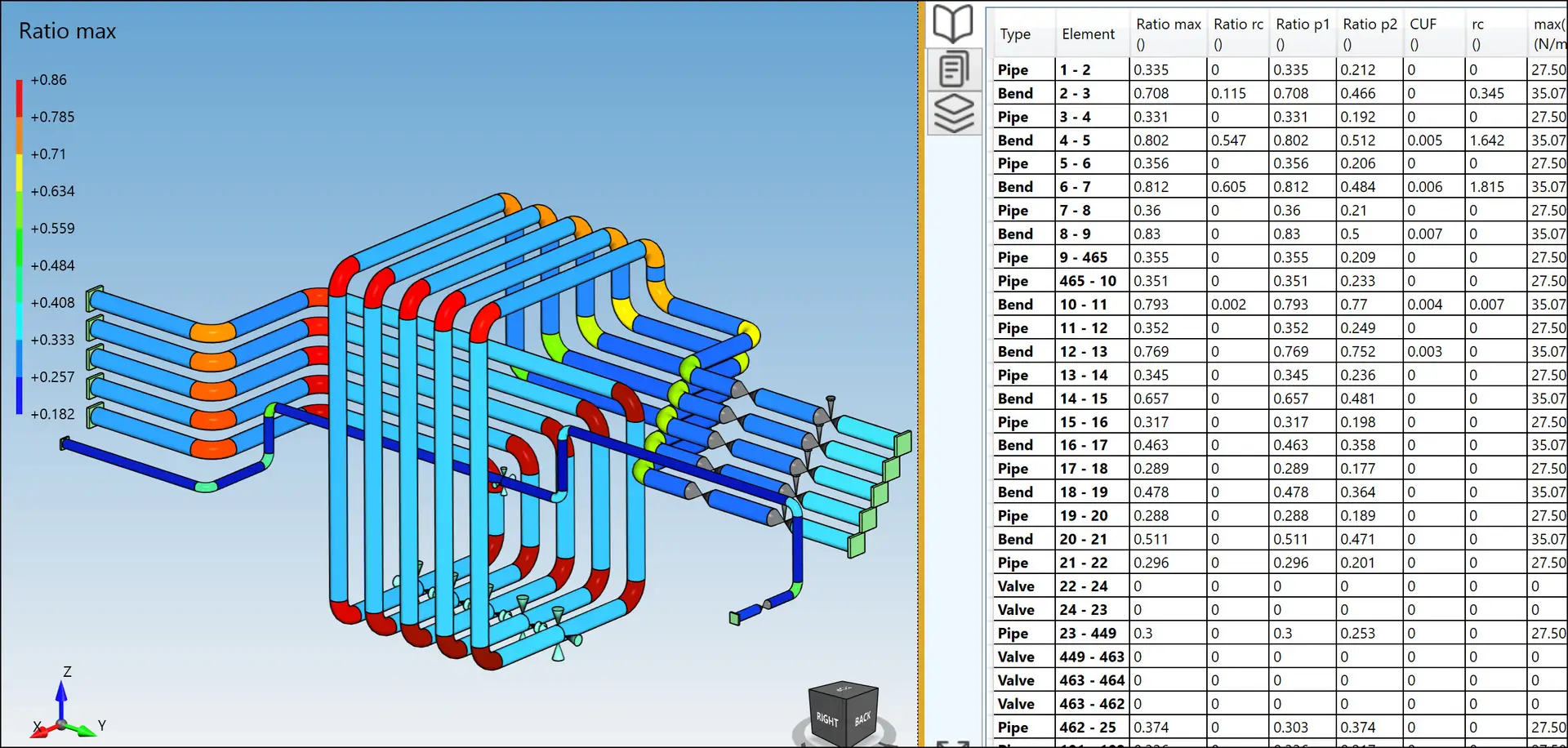

Analysis

Supported codes :

- EN 13480-3 Editions 2017, 2020, 2024 with Table H.3 (bidirectional SIFs)

- RCC-M Class 1 Editions 2002, 2007, 2012, 2016, 2017, 2018, 2020, 2022

- RCC-M Class 2 Editions 2002, 2007, 2012, 2016, 2017, 2018, 2020, 2022

- ASME Section III Class 1 Editions 2015, 2017, 2019, 2021, 2023, 2025

- ASME Section III Class 2 & 3 Editions 2004 + A06, 2007, 2010, 2013, 2015, 2017, 2019, 2021, 2023, 2025

- ANSI/ASME B31.1 Editions 1998, 2004, 2007, 2010, 2012, 2014, 2016, 2018, 2020 (with B31J SIFs), 2022, 2024

- ASME III Appendix XXVI (Polyethylene HDPE Piping)

- EDF HDPE D305921021240 indice A and B

- EDF Composite Piping (E.N.S.IN/91-025 indice D and E)

- RCC-MRx Vol. B Class N1 Edition 2022 (type P and S damages + abatement factor g + fatigue usage + creep rupture)

After calculation the results are shown with tables and color maps. Displacements can be animated.

Results:

- Displacements

- Forces and moments

- Reactions

- Stresses

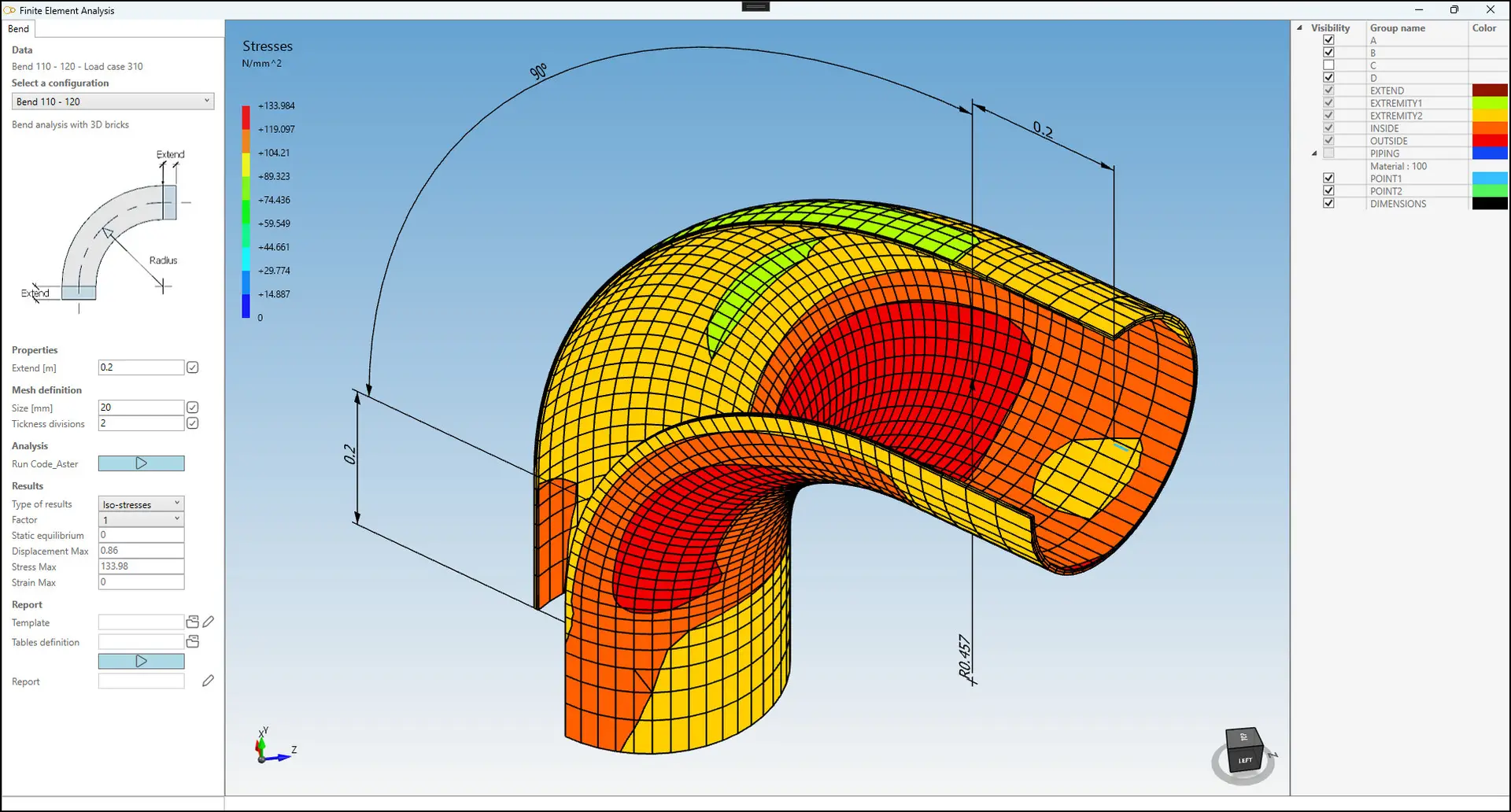

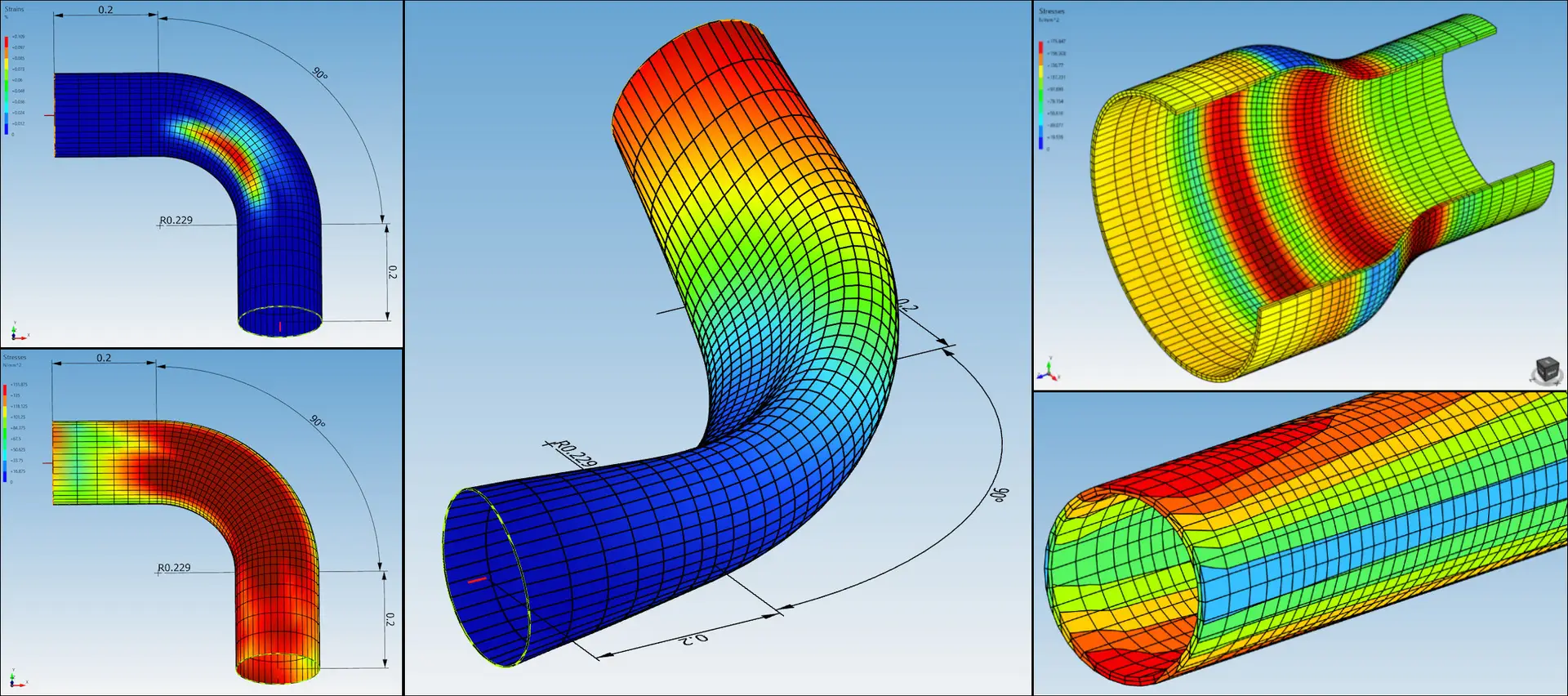

Finite Element Analysis

MetaPiping offers detailed finite element analysis of piping components such as pipe, bend or concentric reducer.

The selected component is meshed with shell or brick elements:

- 3D bricks : second order 20-node hexahedrons

- 2D shells : second order 8-node quadrangles

Loads are then applied on the elements and the boundary conditions are defined.

The solution is calculated by Code_Aster solver.

The results are shown with color maps.

A report can finally be generated.

Results:

- Displacements

- Stresses

- Strains

- Iso-displacements

- Iso-stresses

- Iso-strains

MetaStructure link

Connect one or more structural supports to the piping model and make a coupled analysis in a single pass.

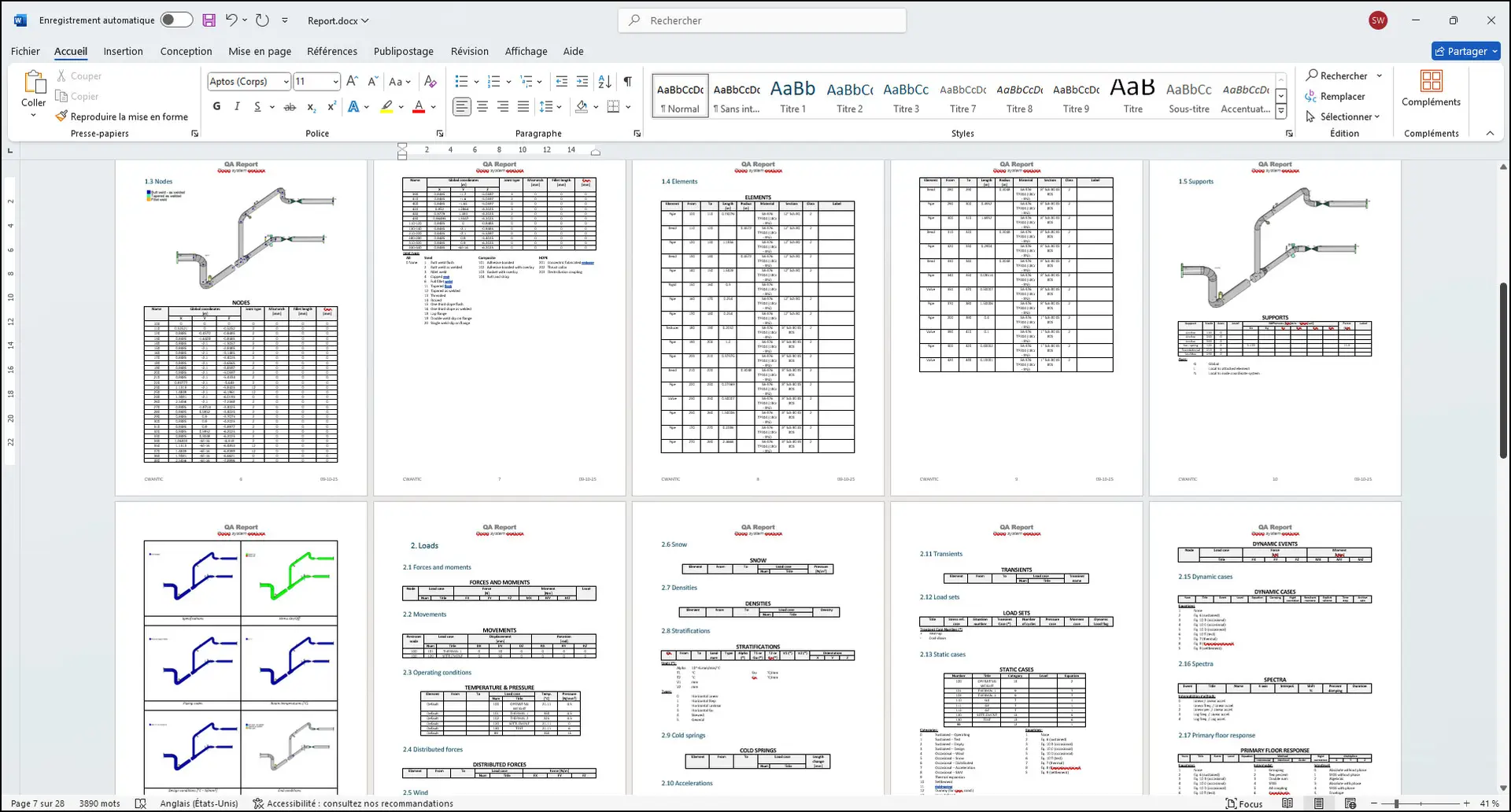

Documentation

MetaPiping can generate reports with all the details of the model input (including graphics), and all results of the analysis.

The report is exclusively based on *.docx file.

A report is based on an empty template (*.docx) that contains keywords.

- Template is a Word *.docx file with user defined layout and content.

- Keyword is associated to a section described in a table document (*.docx).

User can prepare template document and table document and then import them in the software.

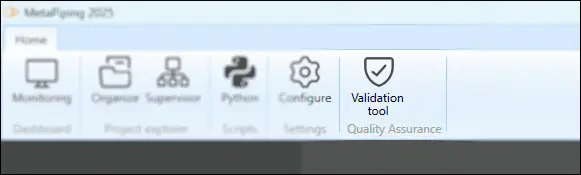

Validation tool

MetaPiping is validated on a large number of test cases.

A qualification document is then established demonstrating the compliance of the software with the most demanding standards of the nuclear industry.

A Validation tool in the Quality Assurance main ribbon executes the analysis of all reference study cases and certify the validity of the software.